Innovation

Over half a century of industry leading innovation in flexible packaging

With a history of innovation that spans over half a century, Constantia FFP are recognised as industry leaders in the design and development of new, innovative and functional flexible packaging.

Our innovations have changed the landscape of flexible packaging within the food industry. We use our extensive material and print knowledge along with our technical expertise to develop practical solutions that add value for our customers and functionality and convenience to consumers.

Constantia FFP Innovation

Industry leading innovation

1978: We developed the first ovenable lidding film for ovenable ready meals.

2005: Estersteam microwaveable packaging was launched.

2013: We launched Estercook, the first fully printed ovenable bag for chickens.

2014: Our reseal technology was launched into Tesco.

2019: Esterseal; the first resealable lidding film in the UK to be classified as Widely Recycled by OPRL is launched.

2019: Our mono material all PE laminate that can be recycled by returning to store is launched.

In House Testing & Development

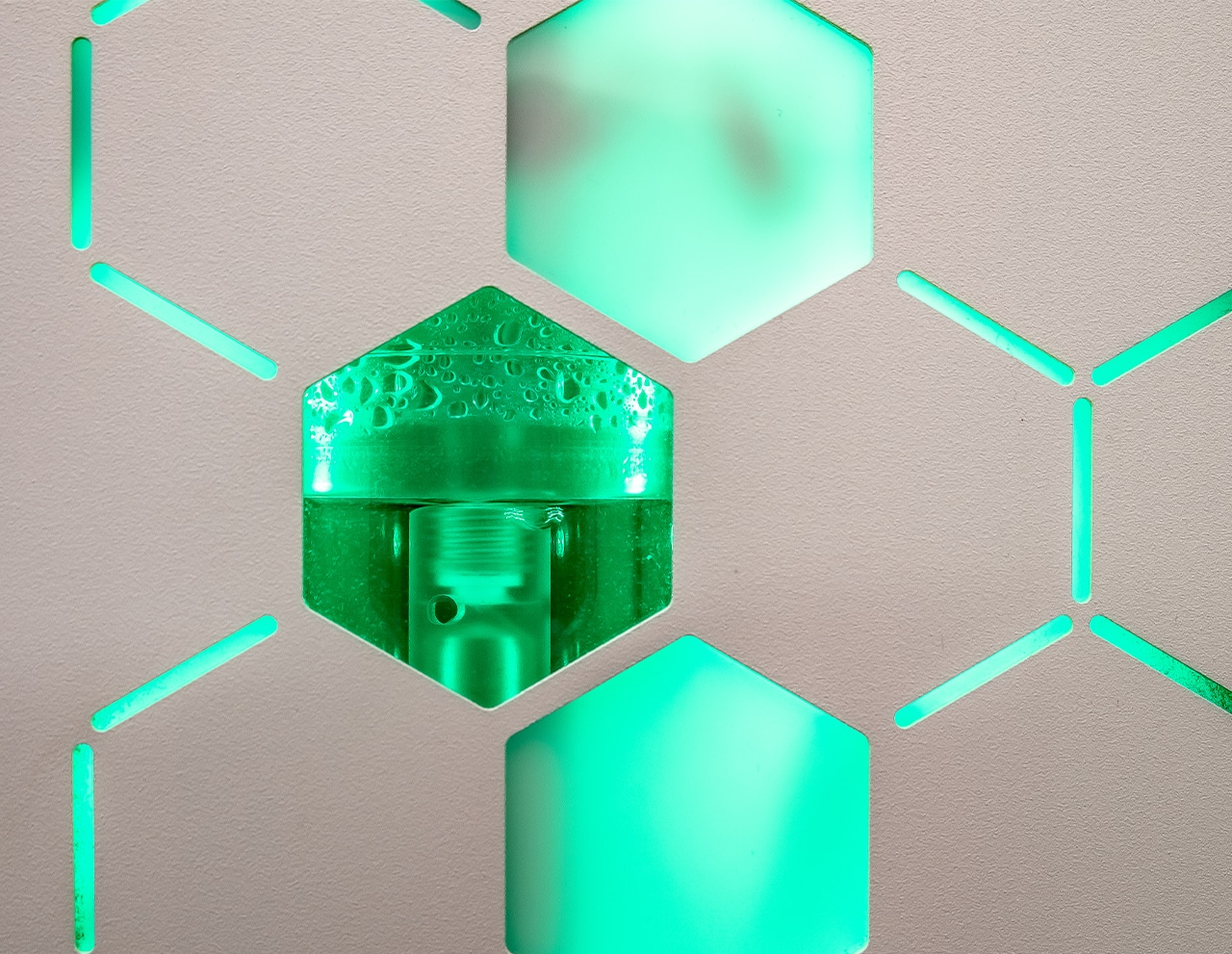

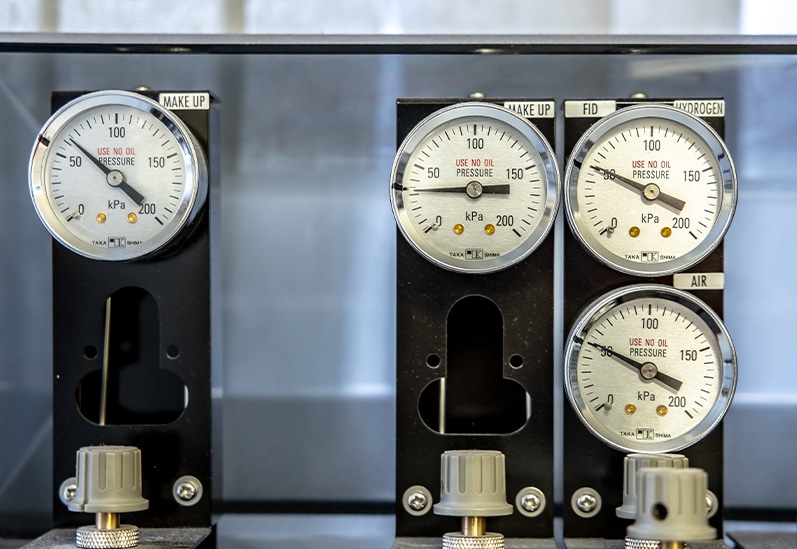

Our new product development team use their exceptional technical expertise and market awareness to develop and rigorously test new innovations before bringing them to market. Our on-site development kitchen and fully fitted laboratories allow us to understand pack performance and replicate ‘real-life’ situations.

Used extensively in the development of new products our labs contain assets such as a heat sealer, tray sealer, leak tester, burst strength tester, hot tack tester and static measuring equipment to name but a few. We can also carry out tests on gas analysis, lamination bond strength and much more. All of these assets perform a vital role in bringing fully-tested and robust products to market.

Industry Recognition

We are delighted to have received recognition from the industry from both peers and customers throughout our history. We have been extremely honoured to receive awards that recognise our innovations for their functionality, sustainable credentials, print capabilities and benefits to the consumer.

We are thrilled to have won the ‘Innovations showcase’ for 2 years running at the Packaging Innovations Exhibition in Birmingham for our work in bringing sustainable and recyclable products to market. This award is voted for by our peers, brands and retailers and is testament to the dedication and commitment of our team in bringing relevant and functional products to market but also the value we place on developing products that have a positive impact on the environment.

Factory Investments

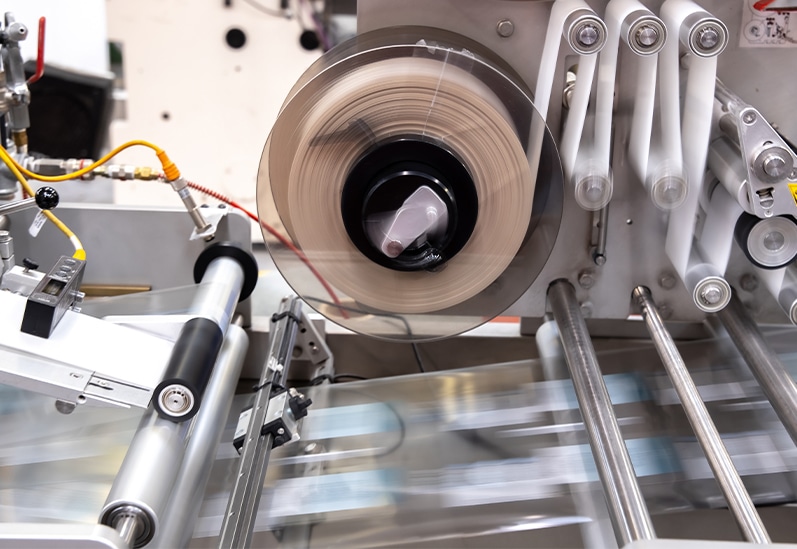

We have identified key growth areas within flexible packaging and responded with new investments to bolster capacity and also provide unique manufacturing capabilities that can path the way for new innovations. With new investments during 2018/2019 in lamination, pouch making and Re-Seal label application systems, Constantia FFP is continually looking forward and solidifying its position as a leading UK flexible packaging innovator.

Capital Free Investment

The success we have experienced in bringing new products to market is underpinned by the knowledge and understanding that we need to increase brand value, functionality and create a benefit for the consumer but without the need for significant capital expenditure from our customers. We use our vast technical expertise to ‘think outside the box’ and develop products that can run on standard, unmodified packing lines.