Whitworths Ltd

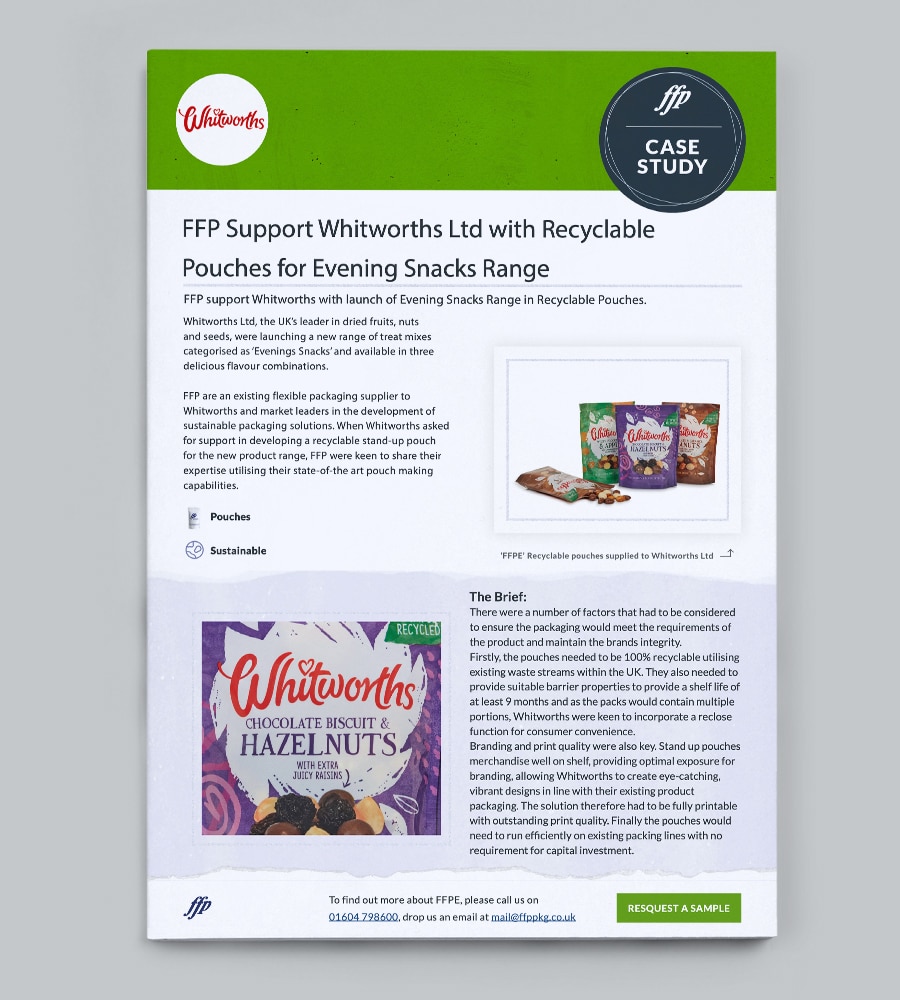

Whitworths Ltd, the UK’s leader in dried fruits, nuts and seeds, were launching a new range of treat mixes categorised as ‘Evenings Snacks’ and available in three delicious flavour combinations.

FFP are an existing flexible packaging supplier to Whitworths and market leaders in the development of sustainable packaging solutions. When Whitworths asked for support in developing recyclable pouches for the new product range, FFP were keen to share their expertise utilising their state-of-the art pouch making capabilities.

There were a number of factors that had to be considered to ensure the packaging would meet the requirements of the product and maintain the brands integrity. Firstly, the pouches needed to be 100% recyclable utilising existing waste streams within the UK. They also needed to provide suitable barrier properties to provide a shelf life of at least 9 months and as the packs would contain multiple portions, Whitworths were keen to incorporate a reclose function for consumer convenience. Branding and print quality were also key. Stand up pouches merchandise well on shelf, providing optimal exposure for branding, allowing Whitworths to create eye-catching, vibrant designs in line with their existing product packaging. The solution therefore had to be fully printable with outstanding print quality. Finally the pouches would need to run efficiently on existing packing lines with no requirement for capital investment.

FFP offered a pre-made, stand-up, doy pouch made of a mono material all PE laminate called ‘FFPE’ that met all of Whitworth’s packaging requirements. It is 100% recyclable as it can be recycled with carrier bags at larger stores, as classified by OPRL.

The pouches were supplied with an EVOH layer to provide oxygen and moisture barrier for product freshness and shelf-life. To address the reclose requirements, FFP provided the pouches with an all PE zip that would maintain the packs recyclable credentials. A tear notch was also incorporated for ease of opening.

The pouches needed to run efficiently on automated filling lines which can be challenging with all PE materials as they have a tendency to stretch and not hold register. FFP however, after a great deal of Research & Development, were able to offer an all PE solution that runs efficiently on pouch machines as well as automated filling machines due to the heat differential between the two layers.

Mark Oaten, Packaging Innovation Manager for Whitworths commented, “The Evening Snacks range was an important launch for us and the packaging was an integral factor. FFP are an existing supplier and we were well aware of the excellent work they have been doing in sustainable packaging. It was therefore a natural progression to ask them to support us with this launch and to provide a recyclable packaging solution”. He continues; “We were delighted with the final packaging, the print quality is excellent and has enabled the range to really stand out on shelf and of course the recyclable credentials of the packs support our sustainable long term objectives.”

FFP’s in-house originations team were heavily involved in the project, providing colour management solutions to maintain brand integrity across the range. It was important that messaging was consistent across all of the products highlighting their environmental credentials clearly on front of pack. This made it easy for consumers to understand that unlike many other pouches on the market, this packaging was 100% recyclable. The pouches were reverse printed which enhanced print quality, increasing vibrancy and ensuring that the print would not diminish over time. Prior to full production, FFP supported Whitworths with trials to ensure the material and pouches ran well on their packaging lines and would meet their requirements.

FFP Packaging Solutions are committed to the development of more sustainable materials and pack formats that can help to reduce the negative impact that some materials can have on our environment. Over the past 12 months, we have brought a number of sustainable packaging solutions to market that can be recycled now in current waste streams.

Download our Case Study

To receive a digital copy of this case study leaflet, please follow the link below.

Share This: