Pouch Making

State-of-the-art in-house pouch making capability

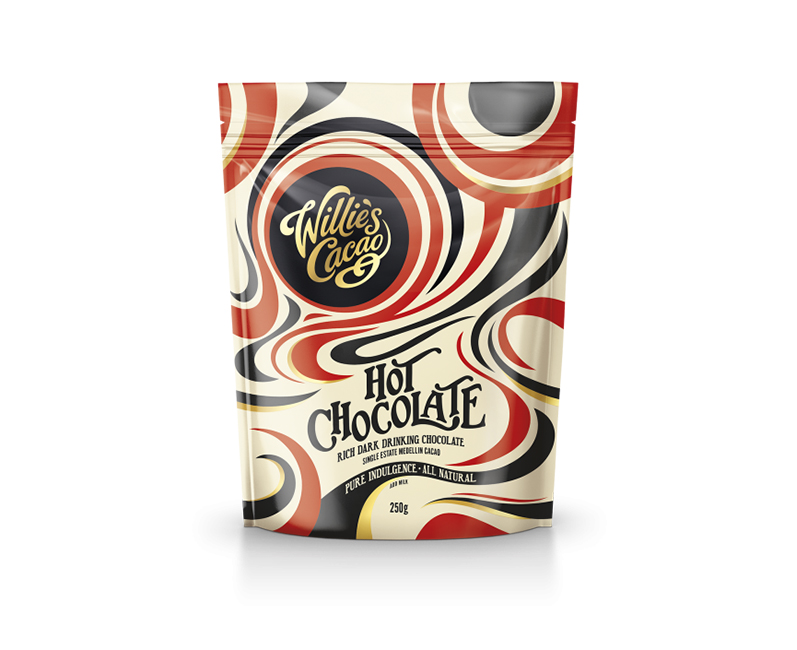

Bags and Pouches are the fastest growing segment of flexible packaging. They offer numerous benefits and options in terms of branding, shelf appeal, functionality and sustainability. Across the retail environment, stand up pouches give dynamic shelf appeal to brands in categories as diverse as ready meals, pet foods, fruit, snacking and confectionery. Brand owners value the full-face branding, efficient use of shelf space and ease of use throughout the supply chain.

Constantia FFP recognised the desire within the industry to move packaging towards a lighter, yet robust solution and we responded by investing significantly in our pouch making capability. We now have two pouch making machines which has substantially bolstered capacity enabling us to respond to market demand.

Constantia FFP Pouch Making

Types of Stand-up Pouches

Doy

The Doy pouch is the most common type of stand-up pouch. It is similar in side view to the K-seal pouch, but has a characteristic rounded base. The Doy style enables light-weight products to stand up as the bottom seal acts as ‘feet’ for the pouch.

- Widths between 100mm and 580mm

- Heights between 100mm (175mm with zipper) and 520mm

- Gusset size between 20mm and 80mm

- Suitable for packaging liquids and fine powders

- Requires a bespoke die

- Can come with features such as zips, press closures, hanging holes and rounded corners

- Laser scoring and tear notches also an option for easy opening

K-seal

The seal resembles the letter ‘K’ and allows more product to be contained near the bottom of the bag. The seals on both sides rise at a 30-degree angle, taking the pressure off the sides of the pouches to allow for additional volume and reduce the risk of puncture or tear.

- Widths between 100mm and 580mm

- Heights between 100mm (175mm with zipper) and 520mm

- Gusset sizes between 40mm and 90mm

- Generally ‘K’ seal pouches expand less and so the same volume of product seems to require a slightly taller bag than the Doy Pouch

- No bespoke die required

- Can come with features such as zips, press closures, hanging holes and rounded corners

- Laser scoring and tear notches also an option for easy opening

V-Seal (also known as a Plough Bottom)

The V-Seal has no seal at the bottom of the pouch as the weight of product sits flush on the bottom of the pouch. It therefore does not require the bottom seal to help the pouch stand erect.

- Widths between 100mm and 580mm

- Heights between 100mm (175mm with zipper) and 520mm

- Gusset sizes between 20mm and 40mm

- Ideal for granular products such as sugar and salt

- No die required

- Can come with features such as zips, press closures and hanging holes

- Laser scoring and tear notches also an option for easy opening

Pre-made bags

Constantia FFP also manufacture a range of pre-made bags.

Options available:

- 2 or 3 side sealed flat bags

- Flat bags central back seal

- 4 side seal gusseted bags (side or central back seal)

Download our Brochure

To receive a digital copy of our pouch making brochure, please follow the link below.

Finishing options

Our state-of-the-art machines allow us to manufacture a full range of printed pouches and bags including; stand-up pouches, two or three sided seal flat bags and four sided seal with gusset. We can offer plain or printed packaging with a full spectrum of finishing options such as;

Tear Notches

Laser Scoring

Reseal Labels

Zips

Carry Handles

Rounded Corners

Micro-Perforations

Key Features:

Our outstanding print and lamination capabilities enable us to offer many decorative and eye-catching solutions such as tactile coatings, paper strip lamination, windows and our own Platinum Print for packaging that really makes an impression and elevates your brand to new heights.

- HD Printing allows eye-catching designs and cover the entire pouch, for powerful shelf presence

- Custom shape and size windows allow for product visibility

- Laser scoring and tear notches allow for easy opening by the consumer

Sustainability

Light-weighting

Pouches can represent a huge weight saving over other packaging products such as glass, pots / tubs and trays. The weight and space savings in transportation and storage can help in the reduction of carbon emissions. There are many opportunities across a wide range of market sectors to move to pouches and reduce packaging weight without compromising on functions such as resealability. It also offers the opportunity to use Constantia FFP’s Platinum Print and various coating solutions to enhance the appearance and feel of your packaging.

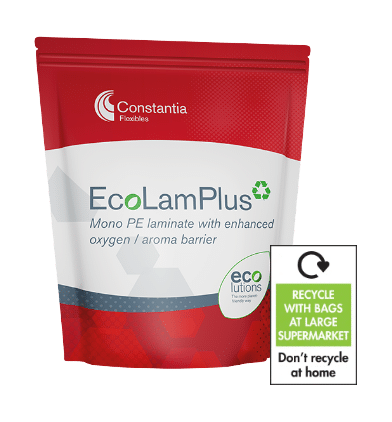

Recyclable Solutions

Addressing the issue of recyclability in packaging, we have developed mono material laminates that can be recycled with carrier bags at larger supermarkets, as classified by OPRL. Available in reel form, as stand-up pouches or pre-made bags, they offer high barrier solutions where gas flushing is required. These products are strong, flexible and lightweight, providing an exciting alternative for companies looking for a recyclable solution whilst still maintaining functionality and creating vibrant shelf-appeal.