Resealable Packaging

Constantia FFP offers a full range of Resealable packaging

Resealable packaging has experienced rapid market growth in recent times. The ability to reseal your lidding film offers numerous benefits such as reduced food waste, easy accessibility, increased consumer convenience and the ability to have a tamper evident mechanism on printed film.

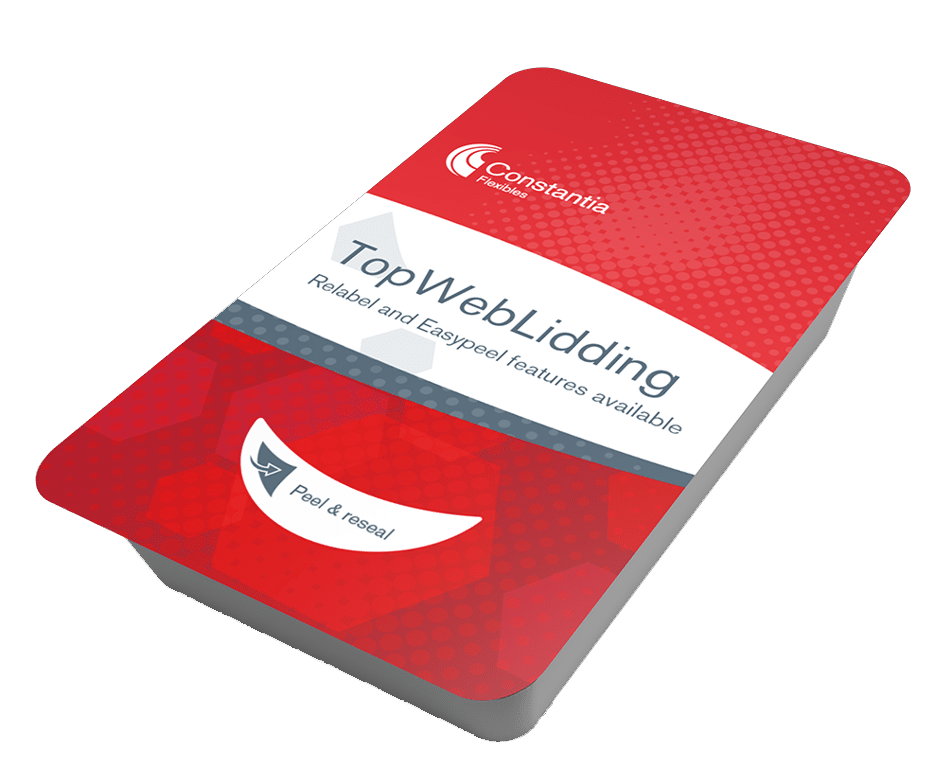

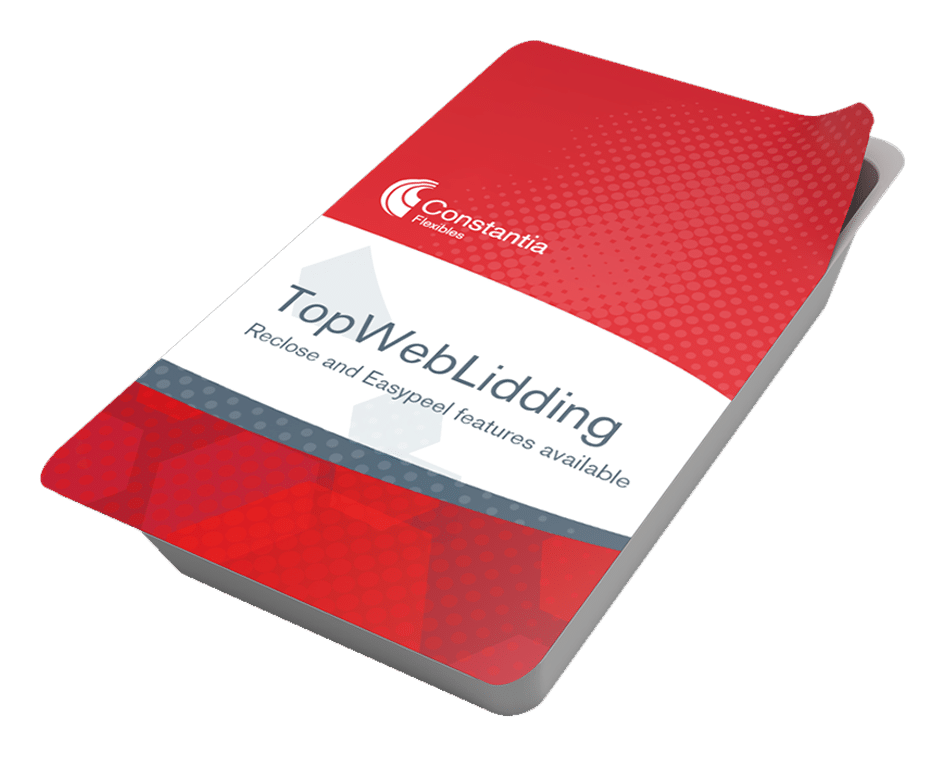

The film can be supplied plain or printed and is ready to run on any standard heat seal line. Both reclose technology and reseal labels are becoming increasingly popular in the fresh and snacking foods markets and in some cases, the use of reseal technology can remove the requirement for a clip-on lid which can offer huge weight savings.

Reseal labels can provide numerous benefits for your brand and products

Such as reduced food waste, easy accessibility, increased consumer convenience and the ability to have a tamper-evident mechanism on printed film.

Constantia FFP can supply film on a reel with reseal labels already applied to your specifications. Used for flow wrap or lidding film applications, the film we supply will be ready to run on any standard heat-seal lidding line that can run registered film. A flexible die is used to produce the easy-access opening and the film is then re-reeled ready to run as normal on your packing lines at your normal production speed with no need for costly modifications.

Increased consumer convenience

Reseal labels are becoming increasingly popular in fresh, snacking foods and bakery aisles thanks to their additional benefits and convenience. They can be resealed multiple times which can assist in maintaining product freshness and they can also be conveniently stacked in the cupboard or fridge so that there is no need to decant the contents into an alternative container. This gives brands a valuable opportunity to maintain visualisation throughout the product’s lifecycle.

Manufacturing capability and capacity

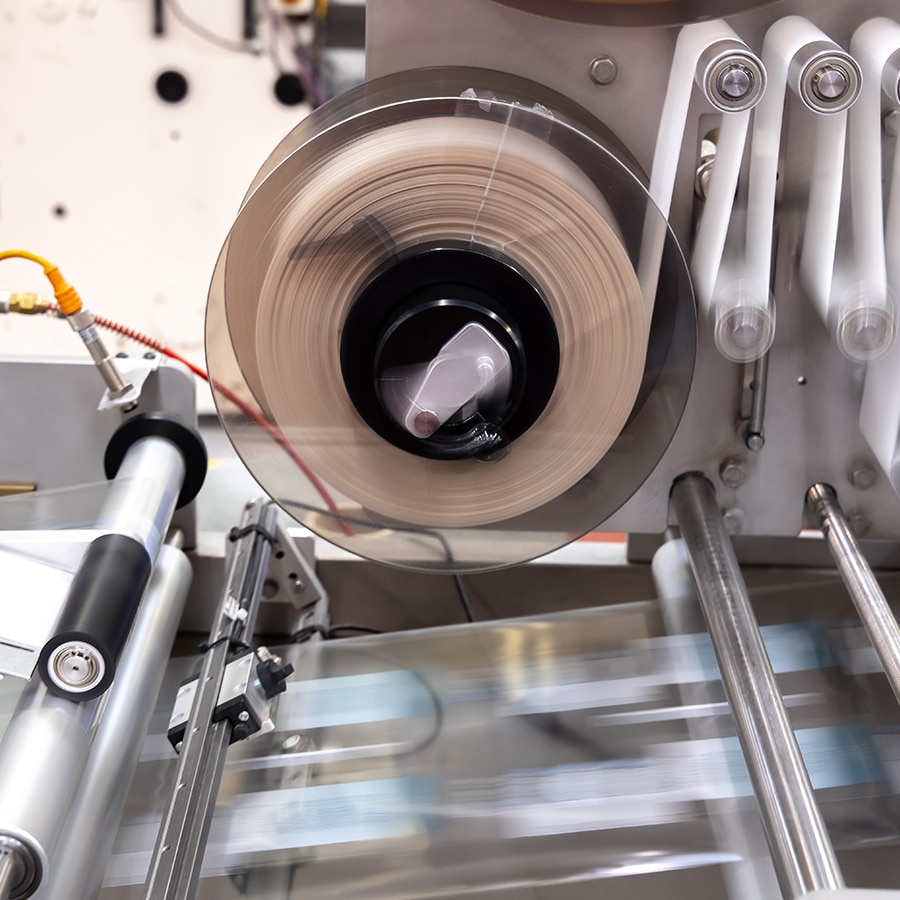

Constantia FFP have responded to the increased demand for reseal labels by installing a third reseal machine at our Northamptonshire-based facility, which will accept film widths up to 650mm, opening the technique to larger flow-wrap formats. The film can be plain or printed and our outstanding print and lamination capabilities allow us to offer many decorative and eye-catching solutions such as tactile coatings, paper strip lamination and our own Platinum Print for packaging that really makes an impression and adds another dimension on shelf.

Recyclable Lidding Film

Constantia FFP have developed a recyclable lidding film that represents a major development in sustainable packaging. The resealable mono material lidding film, available in either PET or PP, has been designed to be used with a tray of the same material to produce the first mono material resealable pack in the UK to be classified as ‘Recycle’ by OPRL and collected in its entirety through the existing waste collection system.

Previously lidding film was unable to be collected and would have to be removed from the tray by the consumer and sent to landfill or for incineration. Constantia FFP’s recyclable lidding film however provides a solution that ensures zero lidding film waste needs to be sent to landfill and instead can be collected at kerbside for recycling.

Reseal Solutions

Constantia FFP have responded to market demand by installing a third reseal machine and in so doing have increased capacity and capability.

The new line will accept film widths up to 650mm, which opens the technique to larger flow-wrap formats. A flexible dye is used to produce the easy-access opening and the film is then re-reeled ready to run as normal on the customer’s packing line with no need for modifications.

Sustainability

Constantia FFP have developed a sustainable packaging solution utilising reseal technology on lidding film to create a recyclable pack that can be collected in its entirety through the existing waste collection system, as classified by OPRL.

Reseal labels applied to lidding film can also offer a lightweight opportunity. As the reseal label can be fully printed it can be used to replace an outer sleeve in certain applications, which can be both commercially and environmentally beneficial.

To find out more about us, please call us on 01604 798600, drop us an email at mail.ffp@cflex.com or visit our contact page.