Lamination and Coatings

Industry leading lamination capabilities and expertise

Constantia FFP is a laminate packaging specialist with decades of experience in developing the right composite structures for our customers’ exacting packaging requirements.

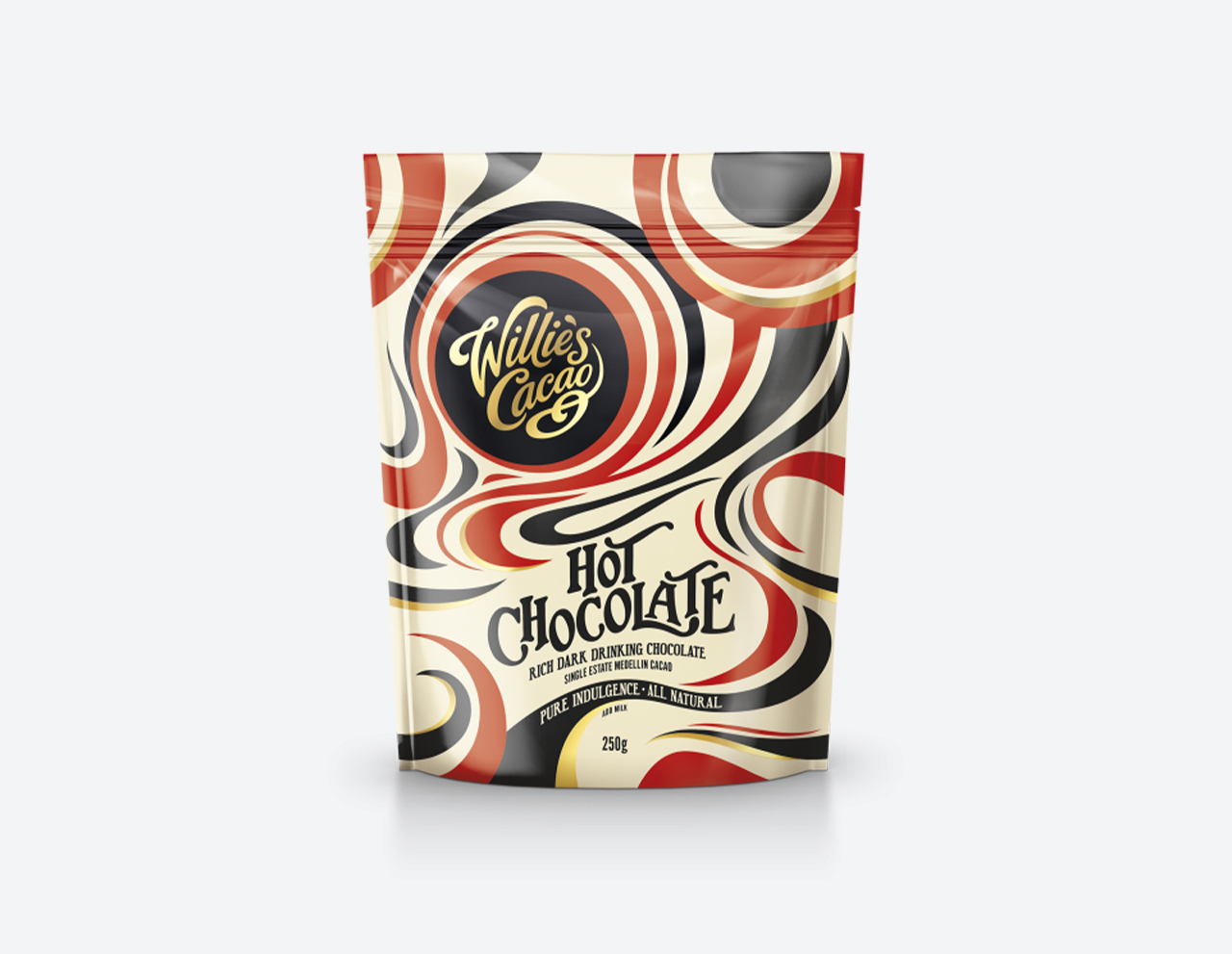

We tailor laminates to suit the product, the packaging machinery and the decorative demands of the pack.

- Solvent based adhesives – fully compliant for ovenable applications

- Increased cold seal capacity – ideal for confectionery and other high speed applications.

- Registered coatings (solvent based & water based) matt, satin, matt tactile and soft touch.

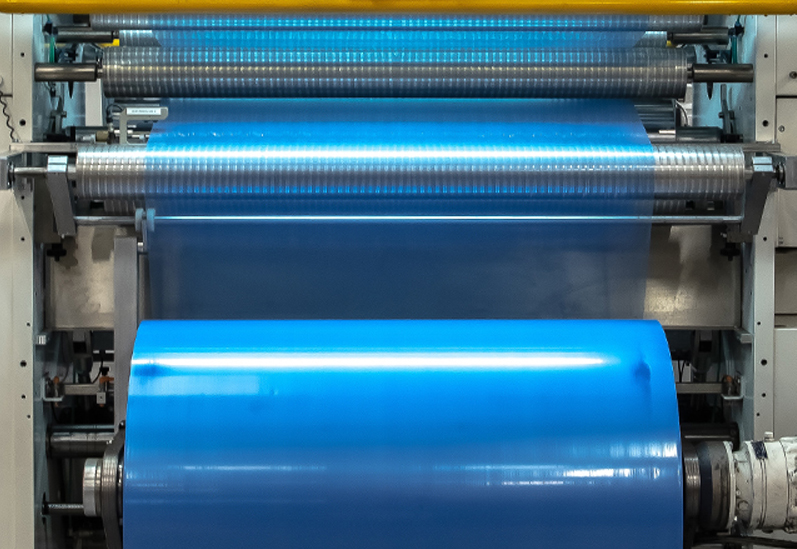

- Lamination width up to 1500mm

- Strip lamination – paper and foil based.

Constantia FFP Lamination & Coatings

Multiple layers for multiple purposes

Flexible packaging is supplied either as a single layer (monolayer) film or as a multi-layer laminate, with layers performing specific functions within the structure of the packaging. The laminate is constructed with high-performance adhesives to make sure they perform superbly on your packing lines and give protection to the product being packed.

Lamination Capability

Our lamination expertise and capability sets us apart from our competitors. With four laminators including the recent addition of a state-of-the-art Nordmeccanica Super Combi 5000, we have not only bolstered capacity, but this investment allows us to apply specialist Gravure coatings that can provide a variety of print effects (matt, tactile, gloss) offering our customers options to perfectly reflect their brand values and aspirations as well as providing eye-catching and vibrant shelf appeal. It has also significantly increased our cold seal capacity, enabling us to respond to increased customer demand across more market sectors.

Materials

Constantia FFP has a strong relationship with a range of leading material suppliers so we can advise on the best possible structure to meet your needs technically and commercially; we build laminates from PET, OPP, PE food packaging, CPP, paper, aluminium foil and many other materials.

Hot Room

Constantia FFP has two dedicated, insulated ‘hot rooms’ maintained at 40°C, allowing us to produce laminates using specialist, high-performance adhesive systems. Our extensive hot room capacity enables us to respond more quickly and with more flexibility to our customers’ requirements.

Download our Brochure

To receive a digital copy of our lamination flyer, please follow the link below.