Design Solutions

From Concept to Completion

Constantia FFP are one of very few flexible packaging converters that can offer a complete solution to your packaging requirements. From the initial design concept all the way through to final production, our team of industry experts can take care of the entire process for you, giving you a local solution which increases flexibility and provides faster lead times.

The Process

We have developed a tried and tested process to take our customers successfully and seamlessly through the design phase of their packaging requirements:

Design & Artwork

Product packaging needs to reflect your brand values, your product and of course create powerful shelf-appeal that engages with your customers, but it must also provide facts and information in a functional format. We offer a design service that takes a project from the initial concept and develops creative solutions along with cutter and tooling layouts to ensure that your packaging can be bought to life effectively.

Mock-Up Samples

We can produce both 3D digital and actual real-life mock-ups of your product packaging in order for you to fully assess your design and its functionality. It is also an excellent tool to allow you to present the packaging concept to colleagues and stakeholders in a tangible format.

Repro Services

We have the expertise and experience in taking an artwork concept and evaluating, then separating the image colours into a printable format for perfect reproduction of the original graphics.

Colour Management

Constantia FFP is committed to outstanding Colour Management and is a registered Pantone® Live printer. The management of colour is a critical part of the control of quality and brand standards and our strict Colour Management workflow system allows us to accurately predict and control colour through pre-press to the final print on press, ensuring brand consistency across the shelf. Every element is measured spectrally to set tolerance’s through X-Rite IQC and X-Rite ColorCert which provides customers with real-time Scorecard data that confirms compliance with specifications, speeds up approval processes and eliminates the need for expensive and time consuming on-site press checks.

Fixed Colour Palette

Through a combination of market leading colour management techniques and state-of-the-art plate and imaging technology, Constantia FFP have gained approval from leading retailers to supply flexible packaging printed with ‘fixed colour palette’ (FCP), saving production time and set-up costs.

A typical design for flexible packaging would be separated using the ‘process ink set’ of cyan, magenta, yellow and black (CMYK). These colours would be used to create the photographic or ‘image’ parts of a pack, accompanied with a number of solid colours for the rest of the design, usually defined by a Pantone® or ‘Special’ colour reference. On certain designs, we can convert Pantone® or special colours to print from the CMYK process set and accurately predict the results achieved on press via an Epson® proof.

Many designs will continue to be produced in the familiar way of using process set and Pantone® colours, however we now have the flexibility to use FCP if a design lends itself to the process.

Using a Fixed Colour Palette can offer significant advantages:

- Easier design and repro

- Savings on plate costs as only CMYK plus white is needed.

- Ink savings

- Increased output and efficiency as quicker make-ready and no wash-ups.

We have defined over a thousand ‘solid’ colours that we can create using the CMYK process set and achieve colour density and repeatability that was previously not possible. We have created our own ‘Fixed Colour Palette Book’, which is a reference library of colours that designers can specify with confidence, knowing that Constantia FFP will accurately replicate that colour on press.

Digital Proofing

Contract Proofs are output in-house from our colour centre using Epson® colour calibrated printers. Proofs are an accurate prediction of colours that will be printed on our WINDMÖLLER & HÖLSCHER Miraflex flexo printing presses and proofs are available on FOGRA certified paper, clear film or metalised film.

We have also recently invested in an EyeC Proofiler system. This state-of-the-art quality control system digitally compares the press print against the customers’ approved artwork ensuring that even the subtlest of differences can be identified and rectified prior to commencing full production and eliminating errors that can cost time and money in reprints, wastage and man hours.

This investment also enables us to compare PDF to PDF files providing further assurance to our customers further into the production process.

HD Plate-Making

Constantia FFP are one of very few converters that produce HD Flexo plates on site. This unique capability allows us to reduce time to market and react quickly to customer requirements.

Flexo Plates are imaged on our Esko Spark Digital imaging machine to 4000dpi. Plates can be processed using solvent or our environmentally friendly water processor that is used in the manufacture of our high quality Platinum Print specification.

Platinum Print

Ideal for brand owners that really want to bring their packaging design to life, our Platinum Print capabilities lift your print into a new dimension with enhanced colour vibrancy and intensity. For packaging that delivers a punch and creates a whole new meaning to shelf appeal.

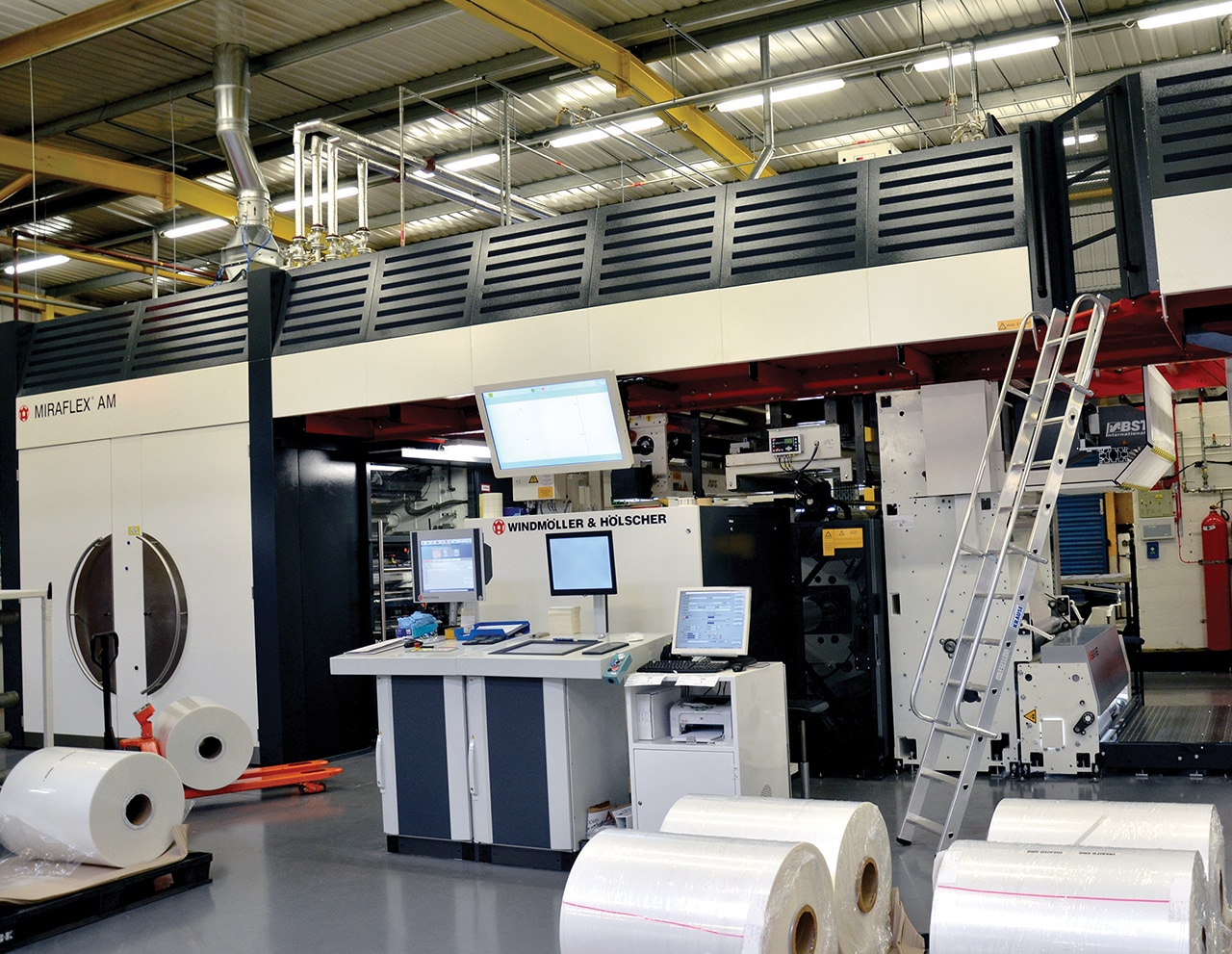

Packaging Production

We have invested heavily in state-of-the-art equipment over recent years in response to market demand for our products. Our Northamptonshire based manufacturing facility boasts two WINDMÖLLER & HÖLSCHER Miraflex flexo printing presses, four laminating machines, with our latest investment allowing us to apply specialist Gravure coatings that can really make your product jump off the shelf. We also have five slitters and two pouch making machines that give us the ability to make bespoke pouches with a wide range of finishes.

Brand Management

For over 55 years, Constantia FFP have been successfully working with brand owners to engage their customers through vibrant, relevant and functional packaging whilst maintaining their brand identity and integrity. Our design solutions team have worked on some of the biggest brands in the country using their expertise along with the most up-to-date techniques and equipment to ensure brand consistency across all ranges.

Design Project Management

All of our customers are assigned a dedicated project manager to take them through the Design Solutions process.

Our team is unrivalled in their knowledge and experience in developing projects from the initial design stage all the way through to production. We will work with you every step of the way offering advice and technical expertise to bring your product successfully to launch.

Download our Brochure

To receive a digital copy of our Design Solutions brochure, please follow the link below.